2020 China New Design Tree Milling Machine Parts - Milled Parts Service – Dongtai Fortune

2020 China New Design Tree Milling Machine Parts - Milled Parts Service – Dongtai Fortune Detail:

Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted material. The milling process requires a milling machine, workpiece, fixture, and cutter. The workpiece is a piece of pre-shaped material that is secured to the fixture, which itself is attached to a platform inside the milling machine. The cutter is a cutting tool with sharp teeth that is also secured in the milling machine and rotates at high speeds. By feeding the workpiece into the rotating cutter, material is cut away from this workpiece in the form of small chips to create the desired shape.

Milling is typically used to produce parts that are not axially symmetric and have many features, such as holes, slots, pockets, and even three dimensional surface contours. Parts that are fabricated completely through milling often include components that are used in limited quantities, perhaps for prototypes, such as custom designed fasteners or brackets. Another application of milling is the fabrication of tooling for other processes. For example, three-dimensional molds are typically milled. Milling is also commonly used as a secondary process to add or refine features on parts that were manufactured using a different process. Due to the high tolerances and surface finishes that milling can offer, it is ideal for adding precision features to a part whose basic shape has already been formed.

Capabilities

|

Typical |

Feasible |

|

|

Shapes: |

Solid: Cubic |

Flat |

|

Part size: |

Length: 1-4000mm |

|

|

Materials: |

Metals |

Ceramics |

|

Surface finish – Ra: |

16 – 125 μin |

8 – 500 μin |

|

Tolerance: |

± 0.001 in. |

± 0.0005 in. |

|

Lead time: |

Days |

Hours |

|

Advantages: |

All materials compatible Very good tolerancesShort lead times |

|

|

Applications: |

Machine components, engine components, aerospace industry, automotive industry, oil & gas industry, automation components. Maritime industry. |

|

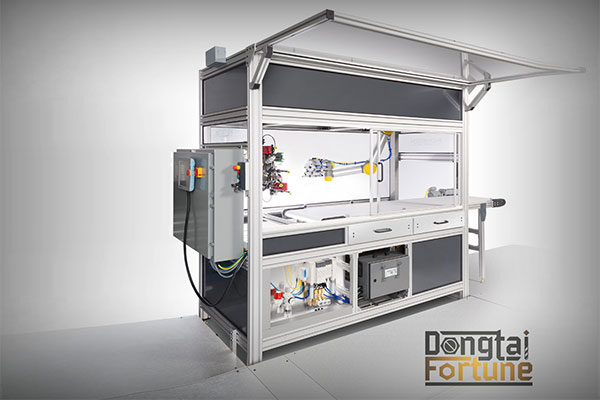

Product detail pictures:

Related Product Guide:

We have been also specializing in improving the things administration and QC system to ensure that we could preserve terrific gain within the fiercely-competitive company for 2020 China New Design Tree Milling Machine Parts - Milled Parts Service – Dongtai Fortune , The product will supply to all over the world, such as: Italy, Burundi, luzern, Now, with the development of internet, and the trend of internationalization, we have decided to extend business to overseas market. With the propose of bringing more profits to oversea customers by providing directly abroad. So we have changed our mind, from home to abroad, hope to give our customers more profit, and looking forward to more chance to make business.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.