Chinese wholesale Milling Long Parts - Milled Parts Service – Dongtai Fortune

Chinese wholesale Milling Long Parts - Milled Parts Service – Dongtai Fortune Detail:

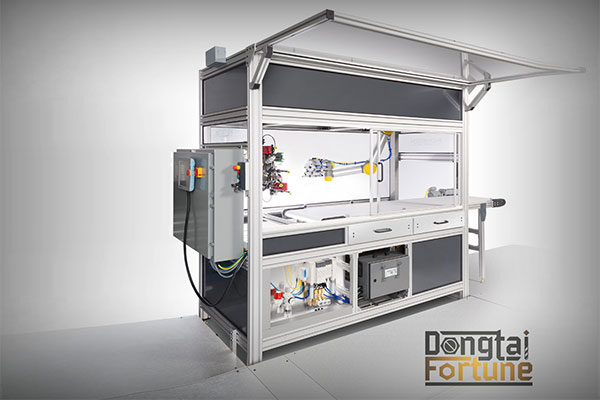

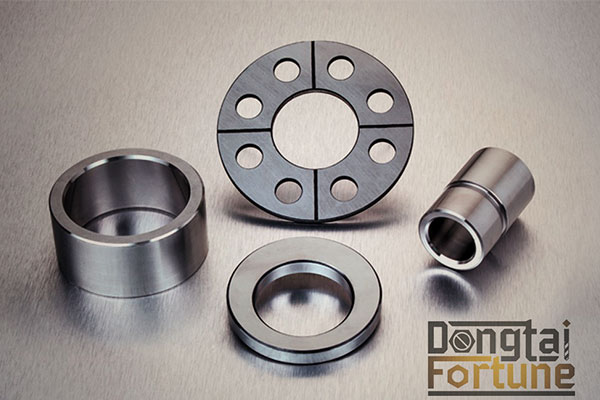

Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted material. The milling process requires a milling machine, workpiece, fixture, and cutter. The workpiece is a piece of pre-shaped material that is secured to the fixture, which itself is attached to a platform inside the milling machine. The cutter is a cutting tool with sharp teeth that is also secured in the milling machine and rotates at high speeds. By feeding the workpiece into the rotating cutter, material is cut away from this workpiece in the form of small chips to create the desired shape.

Milling is typically used to produce parts that are not axially symmetric and have many features, such as holes, slots, pockets, and even three dimensional surface contours. Parts that are fabricated completely through milling often include components that are used in limited quantities, perhaps for prototypes, such as custom designed fasteners or brackets. Another application of milling is the fabrication of tooling for other processes. For example, three-dimensional molds are typically milled. Milling is also commonly used as a secondary process to add or refine features on parts that were manufactured using a different process. Due to the high tolerances and surface finishes that milling can offer, it is ideal for adding precision features to a part whose basic shape has already been formed.

Capabilities

|

Typical |

Feasible |

|

|

Shapes: |

Solid: Cubic |

Flat |

|

Part size: |

Length: 1-4000mm |

|

|

Materials: |

Metals |

Ceramics |

|

Surface finish – Ra: |

16 – 125 μin |

8 – 500 μin |

|

Tolerance: |

± 0.001 in. |

± 0.0005 in. |

|

Lead time: |

Days |

Hours |

|

Advantages: |

All materials compatible Very good tolerancesShort lead times |

|

|

Applications: |

Machine components, engine components, aerospace industry, automotive industry, oil & gas industry, automation components. Maritime industry. |

|

Product detail pictures:

Related Product Guide:

We know that we only thrive if we will guarantee our combined cost competiveness and high-quality advantageous at the same time for Chinese wholesale Milling Long Parts - Milled Parts Service – Dongtai Fortune , The product will supply to all over the world, such as: Jordan, Sri Lanka, Moldova, because of our company has been persisting in the management idea of "Survival by Quality, Development by Service, Benefit by Reputation" . We fully realize the good credit standing, the high quality products, the reasonable price and the professional services are the reason that the customers choose us to be their long-term business partner.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!