Good Quality Hole Making Service – Hole Making Service – Dongtai Fortune

Good Quality Hole Making Service – Hole Making Service – Dongtai Fortune Detail:

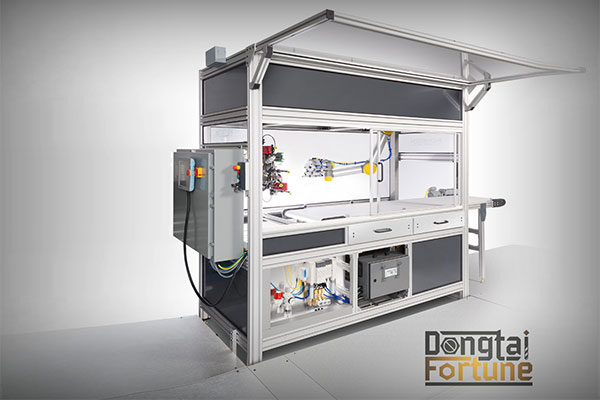

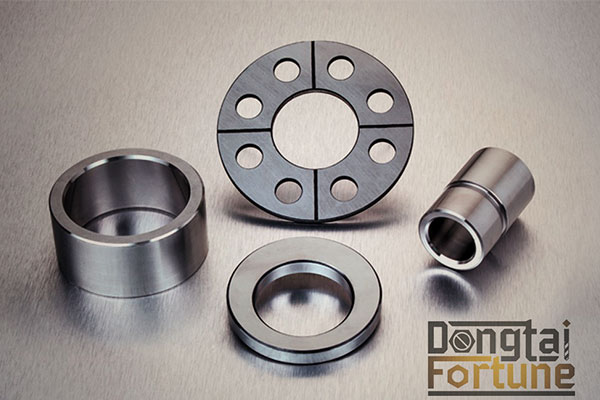

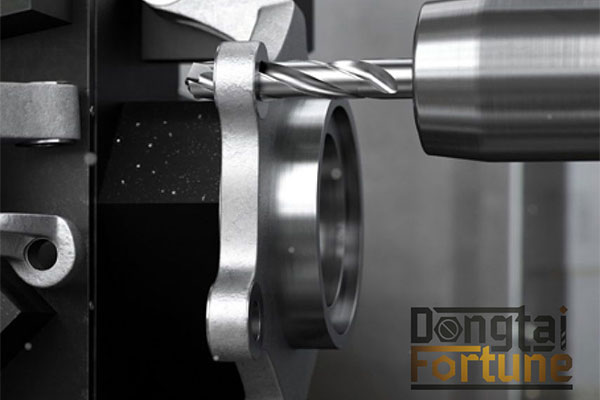

Hole-making is a class of machining operations that are specifically used to cut a hole into a workpiece, which can be performed on a variety of machines, including general machining equipment such as CNC milling machines or CNC turning machines. Specialized equipment also exists for hole-making, such as drill presses or tapping machines. The workpiece is a piece of pre-shaped material that is secured to the fixture, which itself is attached to a platform inside the machine. The cutting tool is a cylindrical tool with sharp teeth that is secured inside a piece called a collet, which is then attached to the spindle, which rotates the tool at high speeds. By feeding the rotating tool into the workpiece, material is cut away in the form of small chips to create the desired feature.

Capabilities

|

|

Typical |

Feasible |

|

Shapes: |

Solid: Cubic |

Flat |

|

Process: |

Drilling, reaming, tapping, boring | |

|

Materials: |

Metals Alloy Steel Carbon Steel Cast Iron Stainless Steel Aluminum Copper Magnesium Zinc |

Ceramics Composites Lead Nickel Tin Titanium Elastomer Thermoplastics Thermosets |

|

Advantages: |

All materials compatible Very good tolerances Short lead times |

|

|

Applications: |

Machine components, engine components, aerospace industry, automotive industry, oil & gas industry, automation components. Maritime industry. | |

Quality Control

Premiere Precision Components’ quality and receiving departments have strict protocols for inspections based on published ISO standards. Our testing methods and procedures are consistent for all products we produce to customers across all industries. This dedication to quality continues throughout our organization with standardized procedures for customer service, accounting, sales, and management activities.

Continuous Improvement

Dongtai fortune has developed continuous improvement programs to develop “best practices” in all situations. When issues arise we address them as a team with sales, customer service, quality, manufacturing and logistics working together to determine a root cause and a strategy for stronger controls. We do this to continually to earn your trust and in order to be your strategic manufacturing partner.

Product detail pictures:

Related Product Guide:

"Based on domestic market and expand overseas business" is our development strategy for Good Quality Hole Making Service – Hole Making Service – Dongtai Fortune , The product will supply to all over the world, such as: Madagascar, panama, Portugal, Honest to every customers are our requested! First-class serve, best quality, best price and fastest delivery date is our advantage! Give every customers good serve is our tenet! This makes our company get the favour of customers and support! Welcome all over the world customers send us enquiry and looking forward your good co-operation !Make sure you your inquiry for more details or request for dealership in selected regions.

This supplier offers high quality but low price products, it is really a nice manufacturer and business partner.