High Quality Metal Fabrication Parts - Steel Metal Fabrication – Dongtai Fortune

High Quality Metal Fabrication Parts - Steel Metal Fabrication – Dongtai Fortune Detail:

Sheet metal fabrication is a classification of manufacturing processes that shape a piece of sheet metal into the desired part through material removal and/or material deformation. Sheet metal, which acts as the workpiece in these processes, is one of the most common forms of raw material stock. The material thickness that classifies a workpiece as sheet metal is not clearly defined. However, sheet metal is generally considered to be a piece of stock between 0.006 and 0.25 inches thick. A piece of metal much thinner is considered to be “foil” and any thicker is referred to as a “plate”. The thickness of a piece of sheet metal is often referred to as its gauge, a number typically ranging from 3 to 38. A higher gauge indicates a thinner piece of sheet metal, with exact dimensions that depend on the material. Sheet metal stock is available in a wide variety of materials, which include the following:

•Aluminum

•Brass

•Bronze

•Copper

•Magnesium

•Nickel

•Stainless steel

•Steel

•Tin

•Titanium

•Zinc

Sheet metal can be cut, bent, and stretched into a nearly any shape. Material removal processes can create holes and cutouts in any 2D geometric shape. Deformation processes can bend the sheet numerous times to different angles or stretch the sheet to create complex contours. The size of sheet metal parts can range from a small washer or bracket, to midsize enclosures for home appliances, to large airplane wings. These parts are found in a variety of industries, such as aircraft, automotive, construction, consumer products, HVAC, and furniture.

Sheet metal fabrication processes can mostly be placed into two categories – forming and cutting. Forming processes are those in which the applied force causes the material to plastically deform, but not to fail. Such processes are able to bend or stretch the sheet into the desired shape. Cutting processes are those in which the applied force causes the material to fail and separate, allowing the material to be cut or removed. Most cutting processes are performed by applying a great enough shearing force to separate the material, and are therefore sometimes referred to as shearing processes. Other cutting processes remove material by using heat or abrasion, instead of shearing forces.

•Forming

•Bending

•Roll forming

•Spinning

•Deep Drawing

•Stretch forming

•Cutting with shear

•Shearing

•Blanking

•Punching

•Cutting without shear

•Laser beam cutting

•Plasma cutting

•Water jet cutting

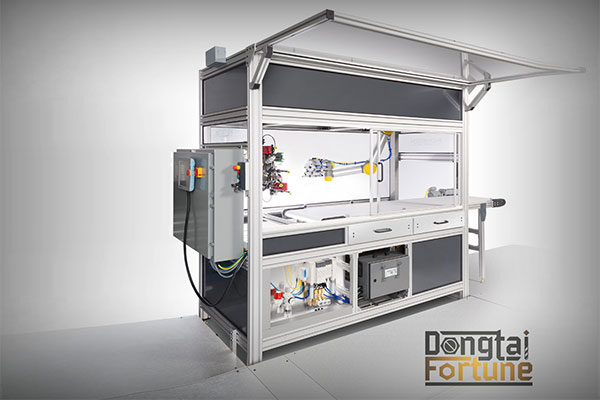

Product detail pictures:

Related Product Guide:

We always believe that one's character decides products' quality, the details decides products' high-quality ,together with the REALISTIC,EFFICIENT AND INNOVATIVE crew spirit for High Quality Metal Fabrication Parts - Steel Metal Fabrication – Dongtai Fortune , The product will supply to all over the world, such as: Moscow, Malawi, Turkmenistan, In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which will be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we are going to continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.