ODM Factory China Custom CNC Parts with CNC Machining for Automation, Medical Industry, Mobile Phone Industry

“Based on domestic market and expand abroad business” is our progress strategy for ODM Factory China Custom CNC Parts with CNC Machining for Automation, Medical Industry, Mobile Phone Industry, Should you pursuit the Hi-quality, Hi-stable, Aggressive price tag parts, business name is your most effective choice!

“Based on domestic market and expand abroad business” is our progress strategy for China CNC Machined Parts, CNC Machining Parts, With the spirit of “high quality is our company’s life; good reputation is our root”, we sincerely hope to cooperate with customers from at home and abroad and hope to build a good relationship with you.

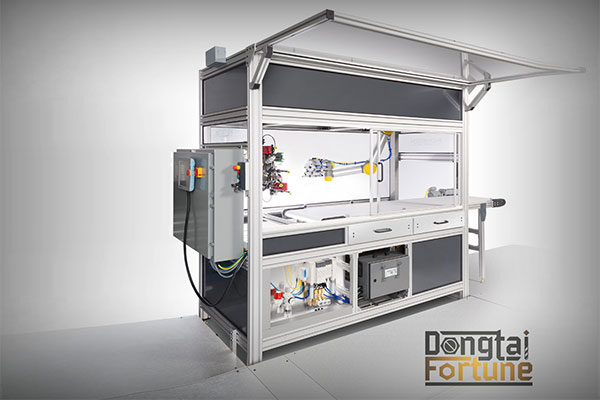

We create custom integrated automation solutions for low-volume and high-volume manufacturing. As an approved Fanuc supplier, our certified automation engineers can create a sophisticated automated program capable of handling all of your manufacturing needs. Our enclousures are built with high-grade aluminum and ultra-clear acrylic, surrounded by a never-slip metal platform, making them among the safest and efficient work environments available.

Each automation system that we build is capable of housing all the components needed for manufacturing, such as: robotics, fixtures, nests, electrical panels, error-proofing, video surveillance, LED lighting and more. And as with every Inovatech automation system that we build, expansion is always planned for. As your needs grow, your system can easily be modified or expanded to effectuate a seamless manufacturing pipeline.

Our Technologies

Our staff has extensive experience with custom automation

systems solutions and practical knowledge of the latest technologies available.

The automation development process includes:

Design

•System Layout Concept

•Quoting

•Cost and pricing

•Mechanical Design

•Electrical Design

•Bill of Materials

•PLC Programing

•Present final designs for approval to begin build.

Automation Build

•Order parts and begin fabrication process.

•Construct enclosure and platform.

•Install robotics, end-of-arm, fixtures and panels.

•Wire electrical panel and program robots.

Systems

•Rotary dial

•Pallet transfer

•In-line

•Robotics

Technologies

•Vision Systems

•Laser Measurements

•LVDT/LDT

•Servo, Stepper & Linear Motors

•Torque Transducers & Amplifiers

•Touch Screen Displays

•Operator Interfaces

• Data Collection

• PC & PLC Control Systems

• Systems Integration & Interfacing

• Training

• Service

Processes

•Assembly

•Inspection

•Packaging

•Orbital Forming

•Impact Forming

•Ultrasonic Welding

•Resistance Welding

•Staking

•Hot Stamping

•Impact Stamping

•Screw Driving

•Pressure Testing

•Leak Testing

•Electrical Hi Pot Testing

•Soldering

DELIVERY

•Teardown and on-site setup of equipment.

•Calibrate robotics and components.

•Validation and operator training.

Markets Served

•Automotive

•Recreational Vehicles

•Consumer Products

•Industrial

•Medical and Pharmaceutical

•HMI Programming

•Machining & Fabrication

•System Build & Installation

•Technical Manuals